Experience Smart Integrated Automation Live At Metaltech 2025

A data-Driven, smart tools built for efficiency, adaptability, and real-time analysis

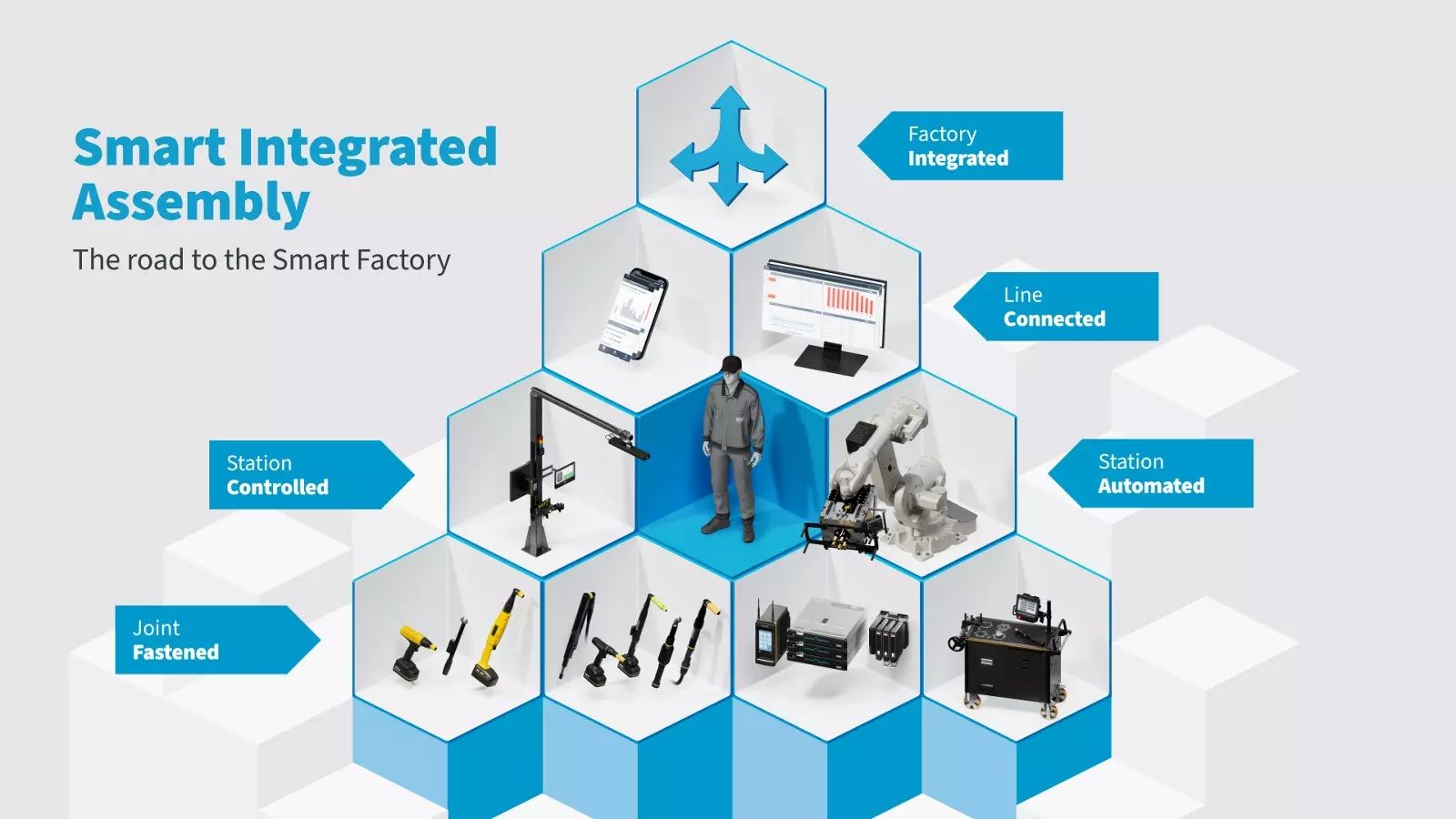

Smart Integrated Assembly enhances traditional methods by using real-time data, IoT, and automation for greater efficiency and precision. It allows flexible production lines that adapt quickly, reducing downtime and errors while optimizing resources, thus boosting productivity and providing continuous improvement insights. Factory assembly faces several key challenges: labor shortages, inconsistent quality, production inefficiencies, safety risks, and the need for greater flexibility and scalability. Manual processes often lead to bottlenecks, human error, and difficulty adapting to new product demands. These issues can slow down production, increase costs, and impact product quality.

DATE May 14, 2025 - May 17, 2025

Venue MITEC Kuala Lumpur

Booth Booth 6140 ( KUKA )

Booth 3130 ( AUBO Cobot )

Automated Assembly Solutions with Quality Consistency, Scalability and Traceability

Witness the Aubo Cobot with Tensor ES tools and the PF6000 controller, designed for seamless integration and flexibility, allowing for easy deployment across various applications with minimal setup time. Finally, explore the Atlas Copco Mobile Cart, a pioneer in smart automation, which enhances productivity by streamlining workflows and reducing downtime, setting a new standard in operational efficiency.

How Atlas Copco Automated Solutions Help You?

Automated tightening and feeding systems speed up assembly processes, reduce cycle times, meeting higher production targets without increasing labor costs. Automation takes over repetitive, heavy, or hazardous tasks, reducing the risk of workplace injuries and improving overall working conditions for operators. Atlas Copco’s modular and standardized platforms allow easy adaptation to new products, changing production volumes, and rapid rebalancing of assembly lines. Solutions are designed to connect with existing PLC and MES systems, ensuring smooth integration with current factory setups. Real-time data collection and analysis enable predictive maintenance, process optimization, and continuous improvement, leading to reduced downtime and higher profitability.

PowerFocus 8 Controller

The PowerFocus 8 Controller stands out with its ability to connect up to six tools simutaneously, significantly reducing the need for multiple controllers and cutting energy consumption by up to 50%.

PF6 Flex System

The PF6 Flex System revolutionizes assembly with its modular design, offering unparalleled flexibility, space savings, and efficiency, making it the ideal solution for modern manufacturing challenges.

Screw Feeder

A screw feeder is a precision device designed to accurately meter and control the flow of bulk materials, ensuring consistent and efficient feeding in various industrial applications.

Avantguard Error-Proofing Software

Avantguard revolutionizes assembly processes with its advanced error-proofing capabilities, ensuring unmatched efficiency and product quality in manufacturing operations.

Fixture Screw Feeding solutions

Our solutions enable you to significantly reduce costs associated with assembly tools while improving the productivity, quality, and ergonomics in the station; as well as providing the flexibility needed in today’s environment of frequent change.

Check Out the Catalog!

- ITBA Tools Catalogue

- Tensor IxB Leaflet

- Toolsnet 8 Leatlet

- Automation Feeding Solutions Leaflet